-

June 5th, 2016, 05:07 PM

#20

What DVM said.

Plus be patient in letting your iron heat up. You'll get nowhere fast otherwise. Mine's just a Radio Shack job (although it does have a stand) and does what I need just fine. I don't do anything approaching DVM-level projects, though.

Axen: Jackson DK2M, Fender Deluxe Nashville Telecaster, Reverend Warhawk 390, Taylor 914ce, ESP LTD Surveyor-414

Amphen: Jet City JCA22H and JCA12S cab, Carvin X-60 combo, Acoustic B20

Effecten: "Thesis 96" Overdrive/Boost (aka DVM OD2), Hardwire DL-8 Digital Delay/Looper, DigiTech Polara Reverb, DigiTech EX-7 Expression Factory and CF-7 Chorus Factory, Danelectro CF-1 Cool Cat Fuzz

"I wish Imagine Dragons would be stuck in an Arcade Fire for an entire Vampire Weekend."--Brian Posehn

-

June 5th, 2016, 05:10 PM

#21

Upcoming NGD and Beginning of Project thread - Blacktop HH Strat

Upcoming NGD and Beginning of Project thread - Blacktop HH Strat

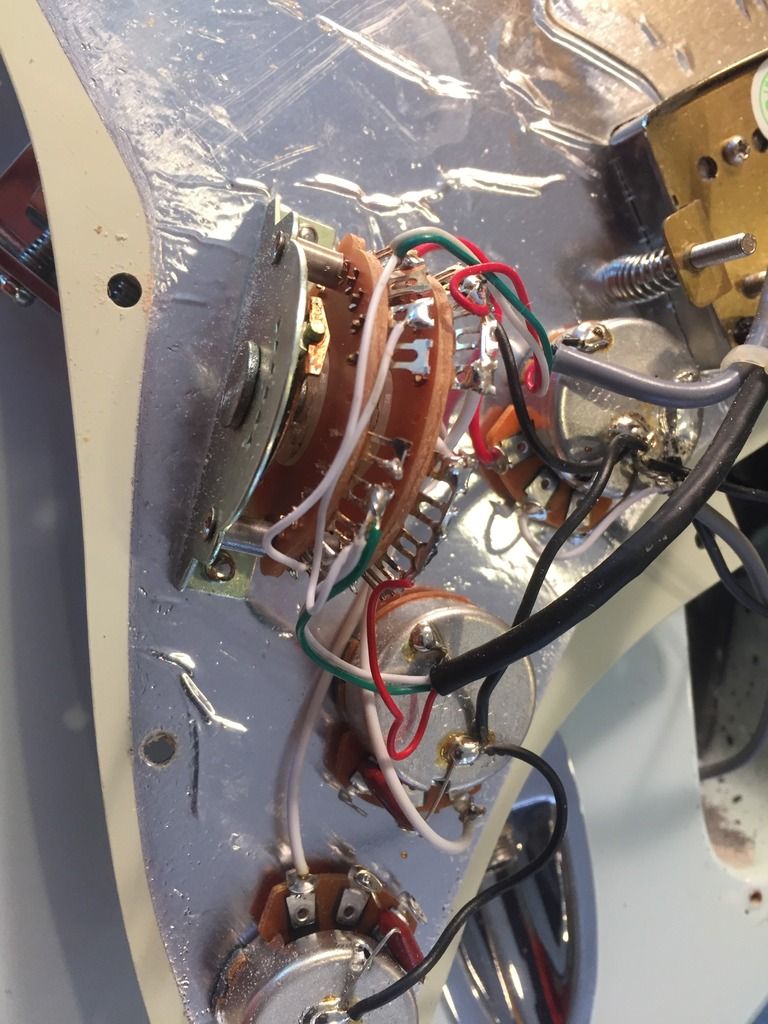

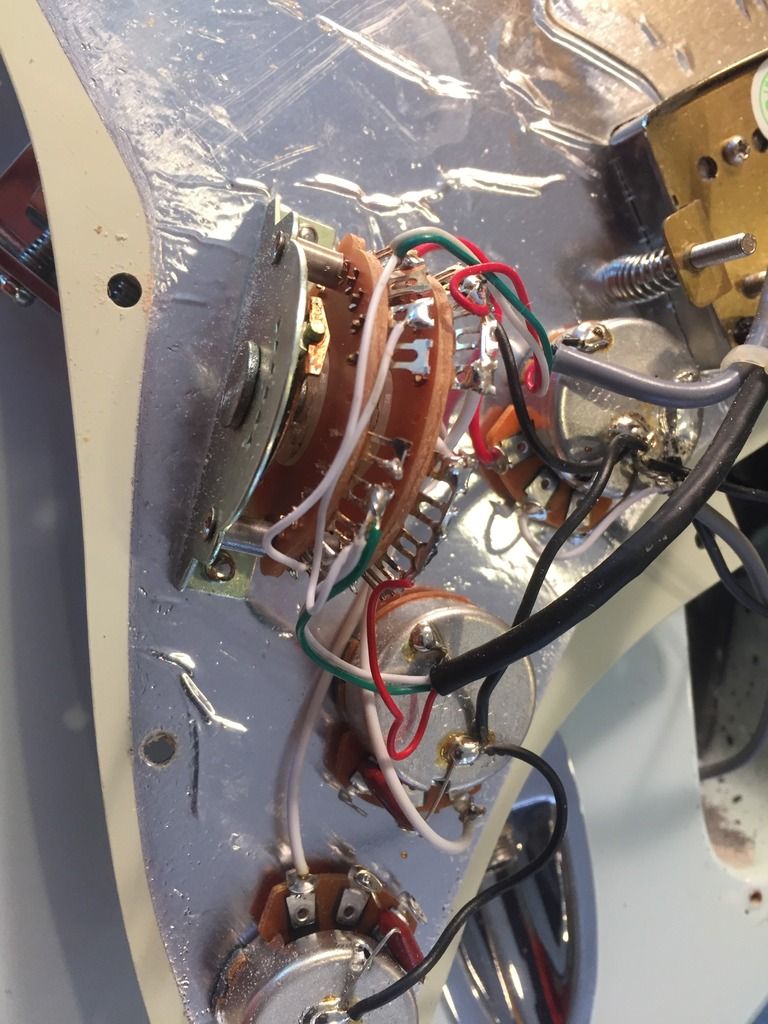

Thanks guys. I attempted it again once I got it heated up properly. Here is the final result of the first attempt before attaching the Jack and ground wires. Probably not the neatest job in the world but maybe it will work. If not, I will have learned before the next attempt.

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 5th, 2016, 08:29 PM

#22

If everything is grounded and the output jack is still wired up, you can test your wiring through an amp by tapping the selected pickup with a screwdriver. You can even test the volume and tone pots from the changes in output sound. Alternatively, you can measure the resistance across each pickup as described HERE. Beats getting everything reinstalled and restrung and then finding out there's a connection problem....

-

June 5th, 2016, 08:48 PM

#23

Upcoming NGD and Beginning of Project thread - Blacktop HH Strat

Upcoming NGD and Beginning of Project thread - Blacktop HH Strat

Originally Posted by

duhvoodooman

If everything is grounded and the output jack is still wired up, you can test your wiring through an amp by tapping the selected pickup with a screwdriver. You can even test the volume and tone pots from the changes in output sound. Alternatively, you can measure the resistance across each pickup as described

HERE. Beats getting everything reinstalled and restrung and then finding out there's a connection problem....

Yes, did that, (saw that tip in the Fender vid I linked) and it was all working. But in triple checking before trying to put everything back in, I found a one loose joint. Fixed that. So will check again later.

So, the tale. I will upload pics in a few minutes after posting via Tapatalk. Easier that way.

So, got the soldering figured out as I said. Got confused on one connection, but I think I have it right. Did the "gross" connectivity test you mention and it seems to work. Did not remember to test the tone pots.

Here is the only stripping tool I have. Will order a better one.

Got excited and decided to put it all back together. BUT . . . when I went to install the wired PG, it would not fit all the way in. Guess what? The screws provided by Dimarzio are too long to fit in the routing of the guitar body. So, I tried to pirate the screws off the stock PG, though I had wanted just to leave that for a later project without messing with the pup mounting in the mint PG. But, guess what? Those screws are too wide! Will not fit in the Dimarzio screw holes. HaHa! So just comical. Oh well. I learned a lot about soldering. The result was a little messy looking, and certainly not up to DVM standards, or probably anyone else's including Marnold's. But it seems to work. If I get it all installed and it is not quite right, or even if I screwed up a stock pot or switch, they are not expensive, and I can get a couple new ones. I was thinking to get a new volume pot anyway for better taper for volume roll down, so if that one does not have clean joints, no big deal. I learned a lot for the next project. Definitely more challenging for me right now than the Santellan solderless kit I used in my tele. But once I get my soldering cleaned up, it will be no big deal.

So, that was the mixed success and lack of success. Perserverance then demanded that I use my time, so I went on and cleaned up the neck using my new files and file guide, and a cheap little file I got as part of a kit to dress the ends once excess material was removed. I then hit the ends with a sanding sponge and steel wool, and then cleaned it all up and oiled the fretboard. Then I put it to bed for the night until i get the correct screws.

All in all, a good learning experience and some good progress was made.

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 6th, 2016, 08:50 AM

#24

Originally Posted by

sunvalleylaw

...I attempted you have attend every time once I got it heated up properly.

Ummm, say what??

-

Post Thanks / Like - 1 Likes

-

June 6th, 2016, 09:09 AM

#25

Originally Posted by

duhvoodooman

Ummm, say what??

Ha! Siri error. I fixed it. I just meant I tried it again after the iron finally heated up all the way. I ordered one of the BYOC ones along with a decent wire stripper for next time.

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 6th, 2016, 12:05 PM

#26

Your wire stripper is far better than mine. I just use the cutting part on my needle nose pliers. As far as soldering quality goes, notice I am careful not to post many pictures of my work here  The only thing I ever had trouble with was getting the claw on my Floyd hot enough to solder the ground to it. I also ended up sanding it a bit to get a better surface to solder to. All I needed was "Yakkity Sax" playing in the background when I was doing that to complete the experience. It wasn't funny then, but it is kinda now.

The only thing I ever had trouble with was getting the claw on my Floyd hot enough to solder the ground to it. I also ended up sanding it a bit to get a better surface to solder to. All I needed was "Yakkity Sax" playing in the background when I was doing that to complete the experience. It wasn't funny then, but it is kinda now.

Axen: Jackson DK2M, Fender Deluxe Nashville Telecaster, Reverend Warhawk 390, Taylor 914ce, ESP LTD Surveyor-414

Amphen: Jet City JCA22H and JCA12S cab, Carvin X-60 combo, Acoustic B20

Effecten: "Thesis 96" Overdrive/Boost (aka DVM OD2), Hardwire DL-8 Digital Delay/Looper, DigiTech Polara Reverb, DigiTech EX-7 Expression Factory and CF-7 Chorus Factory, Danelectro CF-1 Cool Cat Fuzz

"I wish Imagine Dragons would be stuck in an Arcade Fire for an entire Vampire Weekend."--Brian Posehn

-

Post Thanks / Like - 1 Likes

-

June 6th, 2016, 12:24 PM

#27

Originally Posted by

marnold

Your wire stripper is far better than mine. I just use the cutting part on my needle nose pliers. As far as soldering quality goes, notice I am careful not to post many pictures of my work here

The only thing I ever had trouble with was getting the claw on my Floyd hot enough to solder the ground to it. I also ended up sanding it a bit to get a better surface to solder to. All I needed was "Yakkity Sax" playing in the background when I was doing that to complete the experience. It wasn't funny then, but it is kinda now.

I was trying that, but kept cutting the wires. My current stripper is too large for the wires. To get the job done, I ended up heating up the plastic with flame. (read lit it on fire) then blew it out and pulled it over with gloved hands. I attempted not to breathe while doing this.

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 6th, 2016, 04:29 PM

#28

Originally Posted by

marnold

...The only thing I ever had trouble with was getting the claw on my Floyd hot enough to solder the ground to it. I also ended up sanding it a bit to get a better surface to solder to.

This is a common problem. The issue is that the thermal mass of something as large as a trem claw, or even the back of a control pot, is enough that a small iron tip of the kind generally used for wiring work just can't transfer an adequate amount of heat quickly enough to get the substrate above the melting point of the solder. Many people think that the iron itself doesn't have enough power, but that's rarely the problem. The solution is to get a second, larger tip for the iron. See photo attachment below--my wiring/pedal work tip is attached to the iron on the right side, and the larger tip I use for pot grounding, amp work, and soldering to larger substrates is on the left. Its about twice as wide at the tip, but the mass difference is much higher, probably 4 - 5x the small tip. Makes a huge difference. It also helps to use a chisel-style tip--this type will give more surface area contact than a curved conical tip, so quicker heat transfer. And, of course, all of this assumes that you keep your iron's tip CLEAN & TINNED!

Sanding or otherwise roughing up the surface is also a good idea. It doesn't help the thermal mass issue, but it often improves the adhesion of the solder to the substrate surface. A lot of these parts will have a coating of one sort or another that interferes with adhesion--I've seen it cause molten solder to actually bead up on the part surface like a raindrop on a freshly waxed car. But scuff it up with some fine sandpaper and the solder flows and adheres normally.

solder_iron_tips.jpg

-

June 6th, 2016, 05:14 PM

#29

Good info DVM! thank you. Since I have ordered the BYOC economy soldering station, and it is variable setting between 5-40watts, how do I want to set it for doing the type of work I was doing here? I have seen some internet discussion about temps, but have no idea how it translates related to the wattage. Also, I presume there is a good technique for turning it down between periods of work to avoid "blacking the tip"? Any tips for this solder slob?

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 6th, 2016, 06:36 PM

#30

Originally Posted by

sunvalleylaw

Since I have ordered the BYOC economy soldering station, and it is variable setting between 5-40watts, how do I want to set it for doing the type of work I was doing here?....Also, I presume there is a good technique for turning it down between periods of work to avoid "blacking the tip"? Any tips for this solder slob?

I just leave mine set to 700F (~370C) for everything. Since (1) I have had it since late 2009, (2) used it for at least 150 pedal builds plus various other guitar and lighter amp work, and (3) the two tips both look essentially the same as when they were used the first time, I guess I wouldn't worry too much about tip damage at that kind of heat setting. Of course, with a different iron, "YMMV"....but not by that much, I'd suspect.

-

Post Thanks / Like - 1 Likes

-

June 7th, 2016, 02:56 PM

#31

Originally Posted by

duhvoodooman

I just leave mine set to 700F (~370C) for everything. Since (1) I have had it since late 2009, (2) used it for at least 150 pedal builds plus various other guitar and lighter amp work, and (3) the two tips both look essentially the same as when they were used the first time, I guess I wouldn't worry too much about tip damage at that kind of heat setting. Of course, with a different iron, "YMMV"....but not by that much, I'd suspect.

OK, I have no idea how to translate the wattage into temp but maybe the instructions on the BYOC will say, as I bet machines differ. If you know of a general guide to translating what wattage setting, say 35W or 40W equals 700F or whatever, please point this soldering noob in the right direction. Thanks for all your insights!

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 8th, 2016, 11:48 AM

#32

Originally Posted by

sunvalleylaw

OK, I have no idea how to translate the wattage into temp but maybe the instructions on the BYOC will say, as I bet machines differ. If you know of a general guide to translating what wattage setting, say 35W or 40W equals 700F or whatever, please point this soldering noob in the right direction. Thanks for all your insights!

Some soldering stations (like my Hakko) have a controller that is marked in degrees C or F--can't tell from the photo on the BYOC site if the station they sell is one of these or not. I'll see if I can get more info from them...

-

June 10th, 2016, 09:01 PM

#33

Upcoming NGD and Beginning of Project thread - Blacktop HH Strat

Upcoming NGD and Beginning of Project thread - Blacktop HH Strat

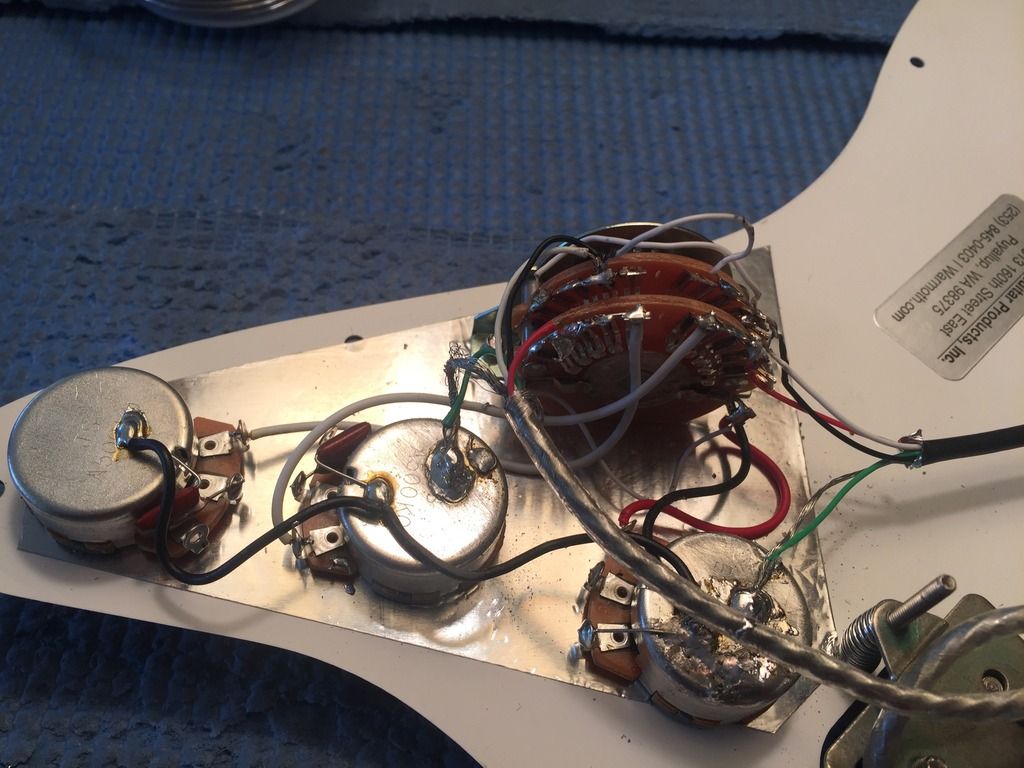

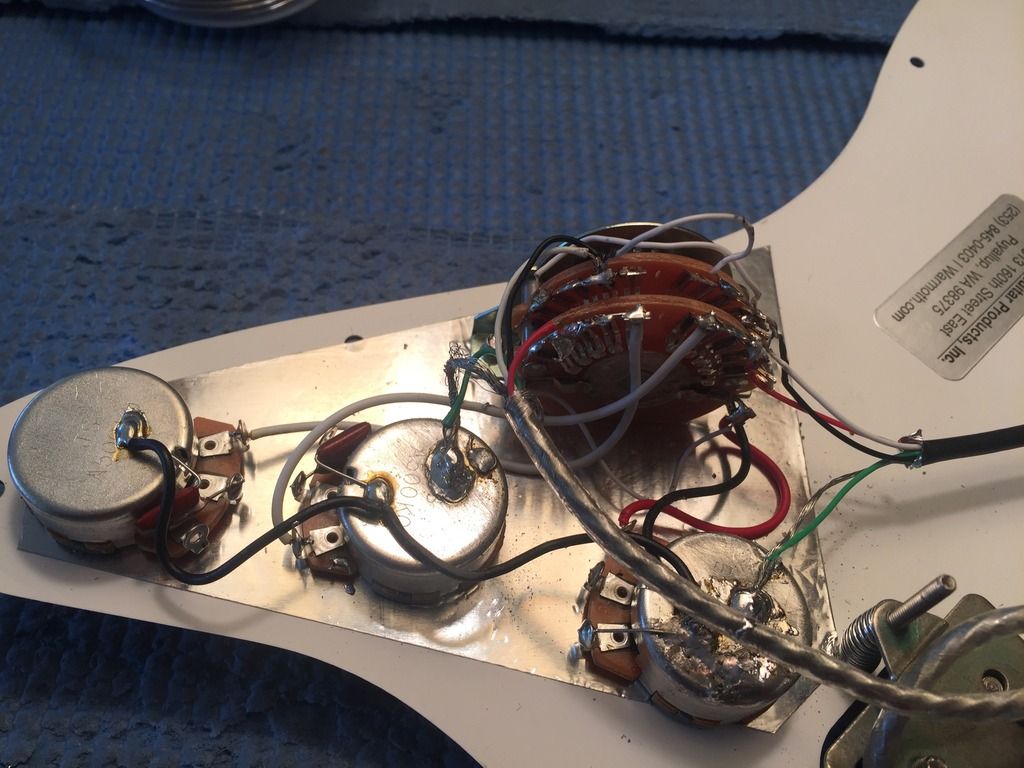

So the new solder station seems really nice. I like the tip size, which is like a finishing nail but more tapered. And the temp control works well. They give you temp ranges in celsius for the markings.

Yeah, ok. It all seemed good as I tried to finish the project. Having the right size screws for the pickups is really nice. But in bench testing it for connectivity, in the middle position, I am missing the inner coil of the bridge. The outer coil toward the bridge is active. So something must be awry with my wiring on the switch. I have double and triple checked it, and it sure looks like I put the wires back where they were when I pulled them off the other pickups. Of course on the Dimarzio it is black and white together rather than green and white. But otherwise, the positions should be the same. Hmm.

Also, in the second and fourth positions, I seem to be getting both lower coils on one, and both upper coils on the other. And I think it should be inner coils on one, outer on the other. So maybe that is messed up too. Hmm. Will have to do some study to see what I can fix before putting it all together.

Wiring stock:

Modded by me with Dimarzios

The rest of it is coming out really nicely. I really like the look of the new pick guard, especially with the zebra picked up. and I have the neck and frets cleaned up and feeling really good.

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 10th, 2016, 11:30 PM

#34

Ok, this seems to help. will open it again over the weekend, and see how things got messed up.

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 11th, 2016, 11:22 AM

#35

For the problem with the inner/outer coils at positions 2 & 4, I would just turn the neck pickup 180 degrees. The other issue with the one coil missing at position 3 sounds like there may be an unwanted connection/short between a couple of adjacent lugs on the outboard side of the switch.

EDIT: See photo attached--is that a solder bridge between the two adjacent lugs?

switch_solder_bridge.jpg

-

June 11th, 2016, 01:30 PM

#36

Originally Posted by

duhvoodooman

For the problem with the inner/outer coils at positions 2 & 4, I would just turn the neck pickup 180 degrees. The other issue with the one coil missing at position 3 sounds like there may be an unwanted connection/short between a couple of adjacent lugs on the outboard side of the switch.

Thanks DVM. That sounds like a possible solution on the coils. I had set them so both sets of wires came off toward the pots. Hmm. Maybe it will work the other way on the neck. It is a swimming pool route. For the other stuff, I may just redo that entire side. I have to re-do the hot wire for the bridge too, as I don't like the joint. The insulation is stripped too far back, and there is no slack.

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

-

June 11th, 2016, 03:28 PM

#37

Originally Posted by

sunvalleylaw

That sounds like a possible solution on the coils. I had set them so both sets of wires came off toward the pots. Hmm. Maybe it will work the other way on the neck.

It'll work unless you have unusually short wires on the neck p/u. You want to keep the connections at the switch the same or run the risk of (a) wiring the two humbuckers out of phase, (b) wiring them so that they hum in combination, or (c) worst of all, both! The inside/outside coil thing is purely to get the added effect of varying physical separation between the active coils of each humbucker when in the 2 or 4 switch positions, so it has nothing to do with the wire connections. When the two inner coils are active, their closer proximity will give rise to greater magnetic filed-induced frequency cancellation than you'd get from the combination of the two outside coils, hence a noticeably different tone. Right now, I'd guess that the tone of those two positions is probably pretty much indistinguishable except for one being a bit more trebly than the other..

Originally Posted by

sunvalleylaw

For the other stuff, I may just redo that entire side. I have to re-do the hot wire for the bridge too, as I don't like the joint. The insulation is stripped too far back, and there is no slack.

Do you have a solder sucker and/or de-soldering braid to clean up the joints after you de-solder the existing connections? Makes a big difference in keeping things neat.

-

June 11th, 2016, 05:54 PM

#38

I have a solder sucker that I ordered when I ordered the solder iron. I left it at work, and i plan on picking it up before I re-do this stuff.

Steve Thompson

Sun Valley, Idaho

Guitars: Fender 60th Anniversary Std. Strat, Squier CVC Tele Hagstrom Viking Semi-hollow, Joshua beach guitar, Martin SPD-16TR Dreadnought

Amphs: Peavey Classic 30, '61 Fender Concert

Effects and such: Boss: DS-1, CE-5, NS-2 and RC20XL looper, Digitech Bad Monkey, Korg AX1G Multi-effects, Berhinger: TU100 tuner, PB100 Clean Boost, Line 6 Toneport UX2, Electro Harmonix Little Big Muff Pi, DuhVoodooMan's Rabid Rodent Rat Clone, Zonkin Yellow Screamer Mk. II, MXR Carbon Copy Delay

love is the answer, at least for most of the questions in my heart. . .

- j. johnson

Reply With Quote

Reply With Quote