Before you go any further, how big is your iron? The size you should be using is like this:

25W

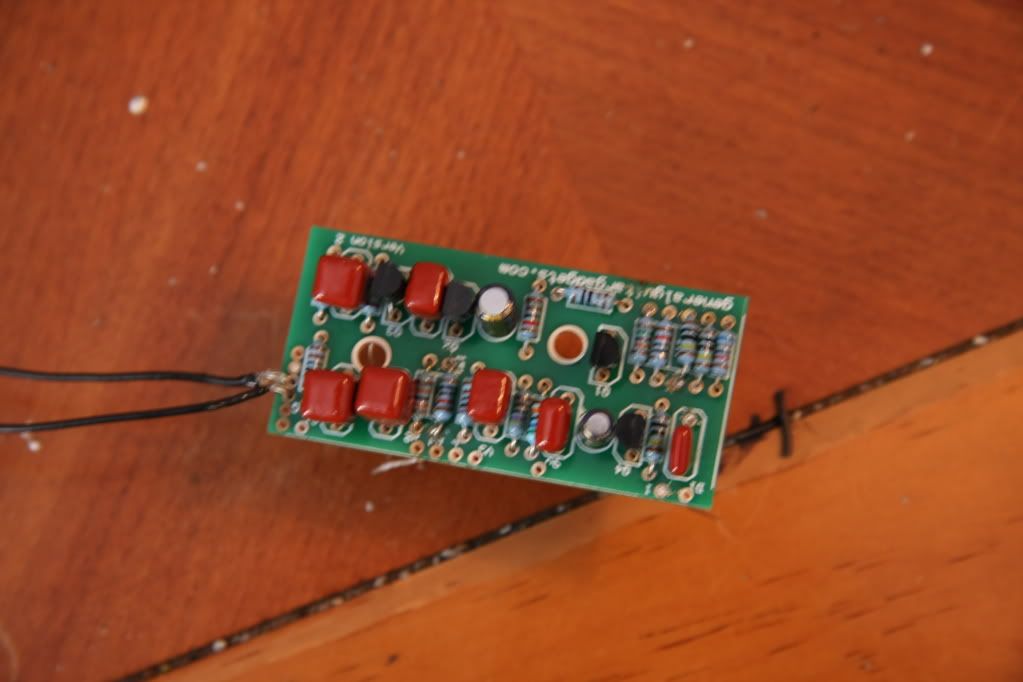

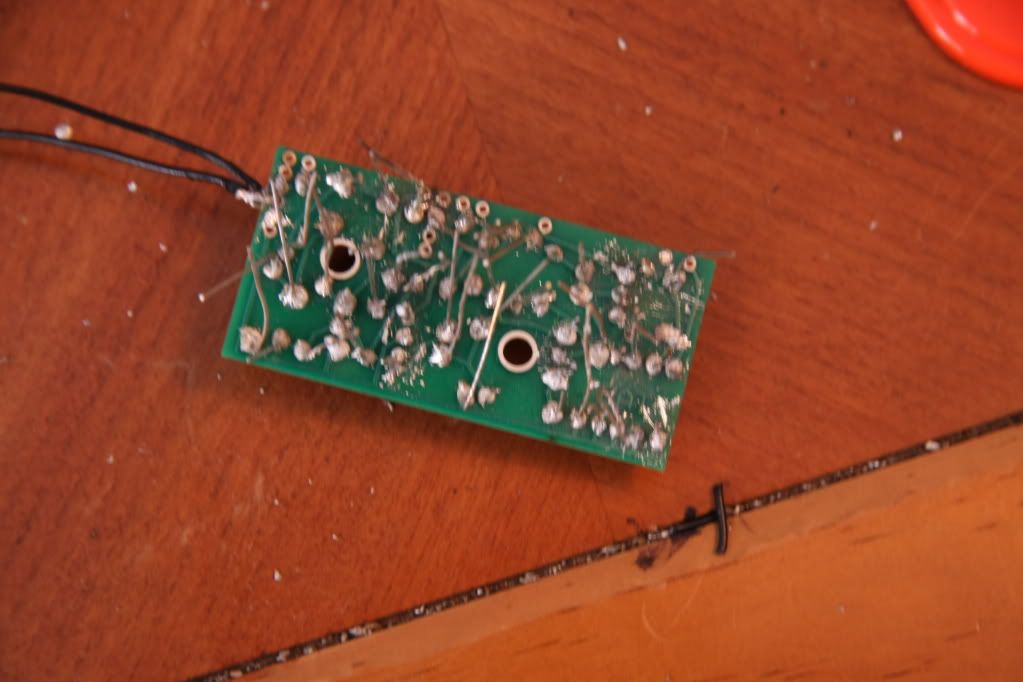

If you're trying to use something much larger than this, you'll get yourself into trouble. Yeah, each solder point should be a "1-shot" i.e you shouldn't try to solder multiple times in the same place. The joints become "dry" (if you look closely, instead of a nice shiny joint (good), it looks cloudy and "bubbly" (bad)). If you show me what you've done so far by way of photograph, maybe I can offer some advice on how to fix it. My job in a previous life was repairing PC and monitor boards, so I have some experience in this area. You can PM me if you like.

Reply With Quote

Reply With Quote